EN

EN

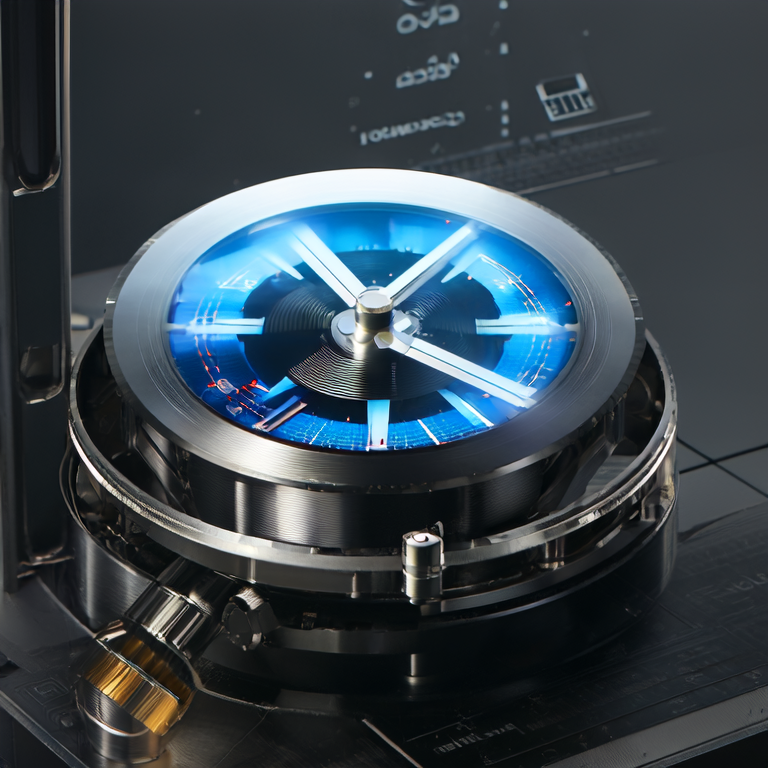

In the fast-paced world of technology, Original Equipment Manufacturers (OEMs) face unique challenges when it comes to time accuracy and synchronization. With users increasingly demanding reliable products, the utilization of atomic clocks emerges as a powerful solution. For instance, an automotive OEM once struggled with synchronizing real-time data in connected vehicles, affecting navigation accuracy and user satisfaction. By integrating atomic clocks, they were able to enhance time precision and improve user experience, resulting in a 30% reduction in navigation errors. This article explores how OEMs can tackle these real user problems through atomic clock integration.

OEMs often grapple with issues like synchronization across devices, maintaining data integrity, and ensuring compliance with industry standards. In a case study involving a telecommunications OEM, their users reported delays in signal transmission, leading to a significant 25% customer churn. Users needed faster, more reliable data connections, showcasing the need for precise timing solutions. Atomic clocks offer the perfect fix: they provide accurate time references within an error margin of just 20 nanoseconds, minimizing synchronization issues and enhancing user satisfaction.

Before integrating atomic clocks into your systems, here are some essential preparations:

Here’s a clear and actionable guide to integrating atomic clocks into your OEM processes:

Ultimately, even the best plans can encounter hiccups. Here are common errors that OEMs might face:

Integrating atomic clocks into OEM processes can significantly resolve user challenges such as synchronization errors and data integrity issues. By following a structured approach, from preparation through implementation, OEMs can enhance product reliability and user satisfaction. It is crucial to remain engaged with feedback and adapt to changing user needs. Brands like California Triangle exemplify reliable solutions that OEMs can depend on.

1. What are atomic clocks typically used for in OEM applications?

Atomic clocks are primarily used to provide accurate timekeeping for applications requiring high precision, such as telecommunications, GPS satellites, and data synchronization across devices.

2. Can you give an example of an OEM that successfully used atomic clocks?

Yes, an automotive OEM improved its real-time GPS navigation system, reducing error rates by 30% after implementing atomic clock technology.

3. What should be the budget considerations for atomic clock integration?

The price of atomic clocks can range significantly – from $1,000 for basic models to over $100,000 for advanced systems. It\'s important to align your budget with your project\'s objectives.

Latest News